Revolutionizing Thermal

Management

Customized aluminum thermal management solutions — including vapor chambers, heat pipes, and liquid cold plates — designed for high-performance cooling in data centers, EV, aerospace, and industrial applications.

Advanced Manufacturing

State-of-the-art aluminum extrusion, CNC machining, and vacuum brazing technologies ensure precise and high-quality thermal products for demanding applications.

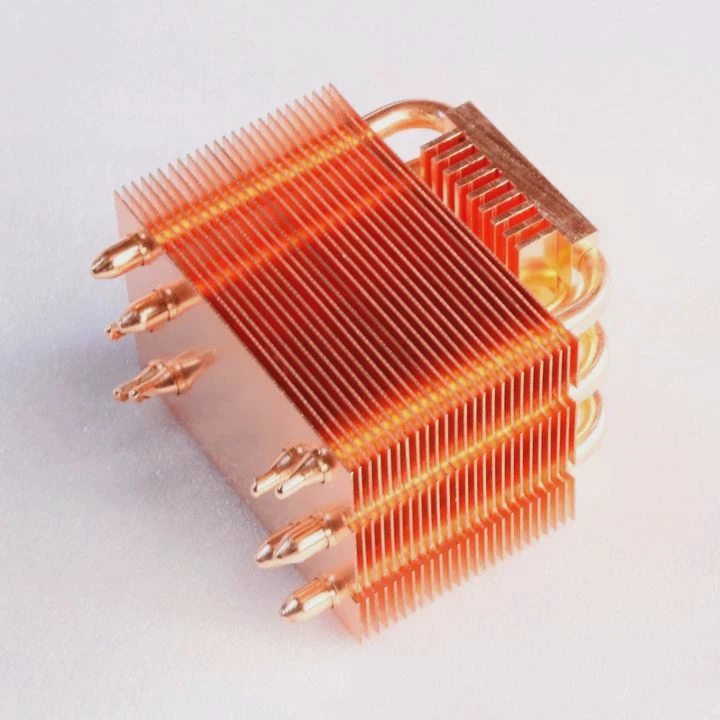

Vapor Chamber & Heat Pipe Technology

High thermal conductivity vapor chambers and heat pipes, enabling efficient heat spreading and cooling for aerospace, EV, and industrial electronics.

Quality & Certifications

IATF 16949 and ISO 9001 certified quality management systems ensure consistent performance and reliability for global OEM customers.

Advanced Thermal Management Solutions

High-performance aluminum cooling systems — including heat sinks, vapor chambers, and cold plates — engineered for demanding industrial and automotive applications.

SinterCool VC

High-efficiency sintered aluminum vapor chamber for aerospace and high-power modules.

Explore

RedunPipe X

Multi-channel flat heat pipe with redundant capillary loops for mission-critical cooling.

Explore

WeldPlate Pro

Vacuum-brazed heat pipe plate providing wide-area heat spreading for EV and energy modules.

Explore

PhaseTherm X

Phase-change thermal plate offering passive temperature stabilization for lasers and satellites.

Explore

HydraPlate LCP

High-capacity liquid cooling plate with precision channels for batteries and data centers.

Explore

ThermoBox A1

Integrated aluminum vapor chamber enclosure combining structure and cooling in one module.

Explore

Core Manufacturing Strengths

We deliver high-performance thermal solutions through advanced manufacturing, engineering expertise, and certified quality systems. Our capabilities cover the full spectrum of aluminum extrusion, CNC machining, vapor chamber and liquid cold plate production.

Precision Manufacturing

Advanced aluminum extrusion, CNC machining, and vacuum brazing ensure exceptional thermal performance and product consistency.

Custom Engineering

Tailored thermal designs for demanding industrial and automotive applications, supported by experienced R&D teams.

Certified Quality

AIATF 16949 and ISO 9001 certified systems guarantee reliable, global-standard quality.

Performance Metrics

Thermal Resistance

↓ 75%

vs. conventional aluminum

Weight Reduction

10 – 50%

with hollow vapor chamber structure

Thermal Conductivity

100× Improvement

Compared to solid aluminum

Power Range

10 W – 10 kW

effective heat dissipation capacity

Thermal Solutions Across Industries

Our AI-powered cooling solutions are transforming thermal management across diverse sectors.

Industrial Automation

High-efficiency cooling for control systems, power modules, and industrial equipment enclosures.

New Energy Vehicles

Thermal solutions for EV battery packs, inverters, and charging systems.

Solar & Energy Storage

Cooling solutions for solar inverters, energy storage systems, and power electronics.

Medical Equipment

Precision cooling for laser, imaging, and diagnostic systems.

Telecom & Rail Transit

Reliable thermal management for communication base stations and rail control systems.

Industrial Electronics

Advanced vapor chamber and cold plate solutions for high-power electronics.

Blog

Volume discount levels for heat sink orders?

Buyers often ask when heat sink prices start to drop with volume. Many worry they’re overpaying for small orders. This guide explains how B2B volume pricing works for thermal components. Heat sink...

Heat sink long-term supply contract options?

Many buyers want stable pricing and reliable delivery for heat sinks. But without a clear contract, risks grow over time. This article explores how to secure better long-term supply deals. Long-term...

Tooling cost for new heat sink profiles?

Many engineers struggle to understand why tooling for custom heat sinks costs so much. They worry about budgeting and production timelines. This article breaks down the cost drivers behind tooling....

Heat sink custom sample process steps?

Sometimes, starting a custom heat sink project feels overwhelming—too many steps, too many unknowns, and too many risks. You want a sample, but not endless delays. The process for requesting and...

Standard B2B terms for heat sink payments?

When buyers and sellers in B2B heat sink markets talk about payment, many don’t fully understand what’s standard. This can lead to delayed orders, miscommunication, and even lost business...

Heat sink pricing factors for large orders?

Heat sinks are vital for many systems. When prices rise, projects stall and budgets break. This problem can hit teams hard without warning. Large order heat sink pricing depends on many factors. You...

Trusted by Industry Leaders

Leading companies across critical industries rely on our thermal management solutions for performance and reliability.

"Your vapor chamber cooling system significantly improved our battery pack thermal uniformity, reducing peak temperatures by 12 °C. It’s been crucial for maintaining EV range and safety."

Li Wei

Thermal System Engineer, EVTech Motors

"The integrated cold plate solution has kept our power control cabinets stable under continuous high loads. Downtime caused by overheating has dropped to almost zero."

Andreas Müller

Operations Director, Siemens Industrial Solutions

"Our MRI cooling requirements are extremely strict. Your customized heat dissipation modules have provided stable operation even during long imaging sessions."

Dr. Emily Zhang

Chief Equipment Engineer, MedTech Instruments

Pioneering Advanced Thermal Solutions

Combining decades of thermal engineering experience with next-generation R&D, our team delivers high-performance cooling solutions for demanding industrial, automotive, and electronic applications.

With patented technologies, global operations, and a dedicated R&D team, we provide reliable thermal solutions that drive innovation across industries.

Innovation & Patents

15+ patents in advanced thermal technologies

Global Reach

Operations in 12 countries

Expert Team

100+ engineers in thermal R&D and manufacturing

Quality Standards

ISO 9001, ISO 14001, IATF 16949 certified

Automated CNC lines ensuring precision and scalability.

Common Thermal Solutions Questions

Answers to the most common questions about our thermal management solutions

Didn't find the answer you're looking for?

Contact Our Technical TeamGet Thermal Management Solutions

Our specialists provide customized cooling and heat dissipation designs for industrial and electronic applications.

Contact Information

Address

Shishan Town, Nanhai District, Foshan City, Guangdong Province, China

Phone

+86 13690695447